|

產品&服務

TOP

產品&服務

PRODUCTS & SERVICE

食品殺菌劑系列食品清潔消毒劑克靈固優勢剖析一、化學特性:主成份為穩定態二氧化氯(Stabilized Chlorine Dioxide),原液呈黃綠色澄清液體,淡氯嗅味,應用濃度下即為無色、無味,於中性偏弱鹼的狀態下使用,無刺激腐蝕。 本品在40℃以下的範圍中,使用效果穩定。殺菌作用機制是反應微生物蛋白質中的氨基酸,令其氧化分解,使它無法再行增殖分裂,且透過氧的方式來交換本質中的電子,所以克靈固對高等動物細胞結構基本上並無影響,也不會與有機載體化合反應,而產生其他附產物如:溴二氯甲烷(CHClBr)、二溴一氯甲烷(CHClB₂)及三鹵甲烷(THMS)等毒性致癌物質。克靈固與細菌、硫化物反應後,其殘留生成物為水、氯化鈉、有機醣及微量二氧化碳等無害物質。 二、克靈固(穩定態的二氧化氯)之特點:目前市售之各類型態之殺菌劑或洗潔劑,雖都各有其優異性,但總觀而言,仍不外乎會出現選擇性殺菌、殺菌不完全、需調整pH值、易與有機物反應,降低效果、易產生抗藥性、泡沫殘留、化學毒性殘留及腐蝕刺激等問題。

三、強效克靈固(穩定態的二氧化氯)之毒性及安全性:本品LD₅₀安全係數極高,依據產地原廠送檢資料顯示,以瑞士種昆明遠交系健康小鼠,每4Hrs餵食2次,檢期為14個工作天測得LD₅₀為5,000mg/kg,再以引起50%受試動物死亡的總計染毒劑量LD₅₀連續染毒20天及一次性染毒劑量造成50%受試動物死亡,得出蓄積系數K小於5,為弱蓄積毒性,另小鼠骨髓嗜多染紅細胞微核試驗結果為無微核作用。 克靈固2000ppm塗敷紐西蘭大白兔之去毛皮膚72小時,無刺激紅腫反應。由上述數據資料中顯示,克靈固強效型HP之毒性對人體是極其安全的。(註記:人類抗體至少高出兔子、老鼠100倍)依據國內食品衛生法規之殘留毒性標準,克靈固強效型HP之各項檢出數據

由表中數據得知,在國內衛生法規標準中,克靈固強效型HP殘餘氯遠低於上限臨界點。 四、克靈固強效型HP應用於蔬果殺菌保鮮:新鮮蔬果從根或莖部摘取後,無法由根莖傳遞補給水份及養份,亦不能行光合作用,為能繼續存活,即從表面及葉片吸收氧氣,蔬果本身酵素使氧氣酸化,造成胺酸燃燒而吐出二氧化碳,這種酵素酸化,燃燒胺酸所產生之乙稀氣就從表面及葉片釋出,因而破壞了蔬果的鮮度。另一個原因即是水份流失。通常新鮮蔬果流失了5%的水份時,即使再注入水份,也無法回復原狀。 此外,影響新鮮蔬果鮮度尚另有一主因,即是附著在蔬果氣孔表面的細菌(包含附著表面的水份中所含有之細菌)。如果能針對這點–即是殺死細菌,就能保持鮮度,克靈固強效型HP(穩定態的二氧化氯)正好切中此一需求,因為產品經克靈固強效型HP(穩定態的二氧化氯)清洗後,反應生成初生態氧,造成蔬果本能反應而緊閉葉片表面水孔氣孔,如此一來,使鮮度降低的乙稀氣就被延緩釋出,同時又消滅附著氣孔及葉片表面水份的細菌,所以就能達到蔬果保存、維持鮮度的功效。 五、結論:降低食品微生物污染是食品殺菌劑或食品洗潔劑的主要商品功能,而克靈固(穩定態的二氧化氯)與市售殺菌劑的最大不同,在於克靈固使用的主輔原料在生產製程符合GHP規範,並依照食品添加物工廠設置標準進行登記與規劃,甚至經食藥署查驗許可核為食品添加物等級的洗潔劑,在全國性產業平台品質系統,克靈固(穩定態的二氧化氯)已連續蟬連SNQ國家品質標章認證,所有作為,都是提昇食品衛生、食品安全及對人體無害,環境友善所產生的附加價值,德啓公司克靈固(穩定態的二氧化氯)用行動來表示我們的道德、良心及熱忱來做到無可比擬之服務的宗旨理念。 克靈固適用範圍

克靈固(穩定態的二氧化氯)食品用洗潔劑系列目前市售殺菌劑,以氯系與氧系較為常見,氯系殺菌劑以次氯酸鈉、次氯酸水最具代表性,氧系則為臭氧、雙氧水、酒精為主,以上雖各有其優點,但都會出現(1)選擇性殺菌、殺菌不完全(2)使用前需調整pH值(3)化學毒性殘留(4)設備氧化腐蝕(5)刺激性氣體外洩(6)產品口感改變等造成食品安全疑慮的問題。 克靈固強效型HP為二代穩定態二氧化氯, 與一般傳統AB劑二氧化氯截然不同,本品經原廠研發人員進行28次的改良實驗,成功開發高純度穩定性二氧化氯,原液稀釋後直接使用,無色無味、並於中性條件下進行殺菌反應,因此效果穩定,二氧化氯不水解,亦不與氨氮及酚類反應,因此不會產生有害消毒副產物,本品於通用濃度下使用,可降低食品總生菌數1000倍,大腸桿菌無檢出。  化學特性:本品由獨特配方6.5% 穩定態二氧化氯(Stabilized Chlorine Dioxide),食品安定劑Na₂CO₃,NaHCO₃、螯合劑及無機抗菌分子等食品添加物組成。在40℃以下的範圍內,質量穩定,外觀為黃綠色透明液體,在建議濃度下操作,可殺滅大腸桿菌、大腸桿菌群、沙門氏菌、金黃色葡萄球菌達99.999%致死率。 傳統氯制劑以變性殺菌,容易造成細菌突變而無法有效滅菌,在反應過程中,也會與有機物化合,產生對人類致癌性的消毒副產物,克靈固的殺菌模式,是氧化微生物蛋白質中的氨基酸,使其細胞失活死亡,這種由內而外殺菌方式,才能完全殺菌,此外,克靈固不水解,不會與氨氮、酚類物質反應,對高等動物細胞結構則基本上無影響,本品最終殘留生成物為水、氯化鈉、有機醣及微量自由有效餘氯等物質。 物性說明:

※了解更多,請電洽食品衛生技術部:03-212-8686

克靈固抗菌除臭劑以往人們廣泛使用的液氯、漂白粉、次氯酸鈉等氯系列消毒劑,但在消毒滅菌的同時,卻與水中的腐殖酸(HA)等有機物發生反應,導致產生致癌、致突變作用的三鹵甲烷、氯仿等氯代有機物,危害人體健康。克靈固不存在因氯化污染的問題,因為克靈固可以氧化水中的有機物、無機物,但不會如氯制劑產生副產品具有致癌、致突變作用的三鹵甲烷、氯仿等有害物氧化成無害的醌式結構物。其作用機理是靠釋放兩次氯酸分子、新生態氧(原子氧),使微生物菌體蛋白中的氨基酸氧化分解,並與空氣中或物體表面的氨、硫化物、有機物相互作用,進而去除有害殘留。在整個氧化過程中,克靈固消毒劑不產生氯仿等有害物,其生成物為水、氯化鈉和微量的二氧化碳、有機醣等無害物,也不會產生氯氣,沒有刺激性。

器具機台消毒劑克靈固應用於食品容器及機台消毒,具有效果穩定,基本上可忽略對不鏽鋼材之腐蝕性,主成份二氧化氯為准用於食品容器消毒物質,一般應用於食品加工設備消毒建議如下:

食品用清潔去污劑克污PLUS,是唯一不受水質硬度影響去污效果之非離子型界面活性劑,本品主成份為短鏈式月桂醇,含天然棕櫚油,中性溫和,無腐蝕及刺激問題,本品不含壬基苯酚,生物分解度達80%,在自然界可完全分解,是與綠色環保標章同等級之天然清洗劑。

應用於食品廠清洗作業時,克污優異的乳化力可快速滲透分解油脂,有效清除食品器械表面細菌與污物,且中性皂劑泡沬細緻,容易沖洗無殘留與安全問題,節省能源與人力。

※了解更多,請電洽食品衛生技術部:03-212-8686

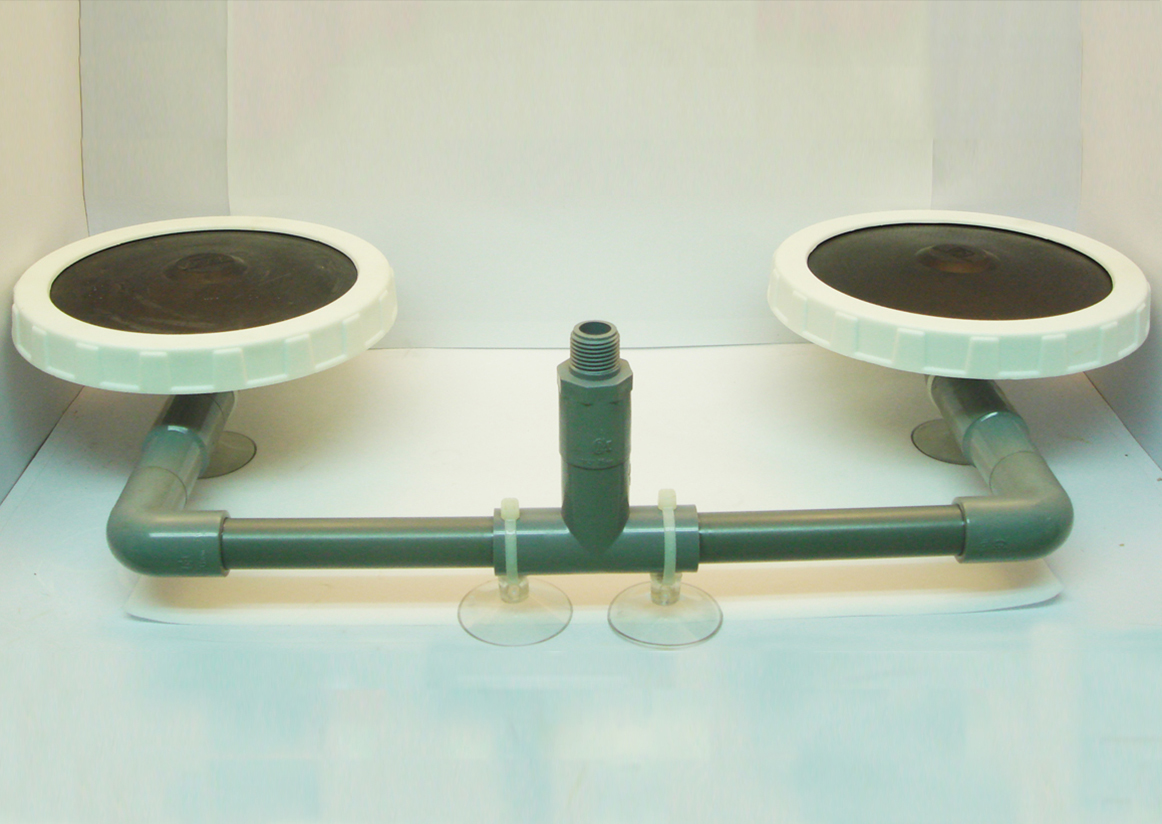

週邊設備產品三盤式曝氣裝置成品圖    加壓式噴灑器   |

生鮮蔬果清洗保鮮

生鮮蔬果清洗保鮮 電宰分切肉品保鮮

電宰分切肉品保鮮 瓶罐容器消毒

瓶罐容器消毒 製冰、飲用水水質處理

製冰、飲用水水質處理 空間落菌控制

空間落菌控制 廢水處理 (降低BOD)

廢水處理 (降低BOD) 雞蛋孵育場抗菌

雞蛋孵育場抗菌 飲料乳品管路消毒

飲料乳品管路消毒 水產養殖水質處理

水產養殖水質處理 工業冷卻水塔消毒

工業冷卻水塔消毒 異味控制

異味控制 水產品儲運保鮮

水產品儲運保鮮 洗選蛋清洗殺菌

洗選蛋清洗殺菌 設備機台表面消毒

設備機台表面消毒 溫游池、溫泉SPA館水質管理

溫游池、溫泉SPA館水質管理 花卉保鮮

花卉保鮮